The evolution of an idea

Some Reef Keepers are more passionate about equipment than their fishes and corals, ourselves included. Our addiction to automation, together with more then 30 years of software development and reef keeping experience, lead us to start Invent Marine.

In this post we will share some of the steps we went through, in terms of going from a prototype to a product.

This was our very first prototype. It was basically an ATO and a temperature sensor, hooked up to an Arduino. Notice the “eco-friendly” cardboard enclosure.

Simple ATO, using a peristaltic pump, an Arduino and a cardboard enclosure.

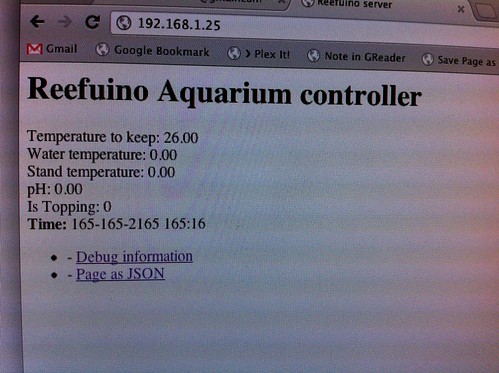

It was about time to add a screen to the prototype, so we’ve added an 4.3″ touch screen and an ethernet card to the soup. This was pretty much the same hardware that powers the Jarduino, the popular Arduino controller. Fortunately, we quickly figured out that such a small, irresponsive and not visually appealing screen, wouldn’t help to achieve the quality we were looking for.

As you can see in the screen, this prototype was kindly called Reefuino.

Almost at the same time, we kicked off the web interface and remote REST API. It also didn’t take long to realise the Arduino platform isn’t powerful enough to host a web server to the extent we were aiming. Its programming was difficult and performance was unacceptable.

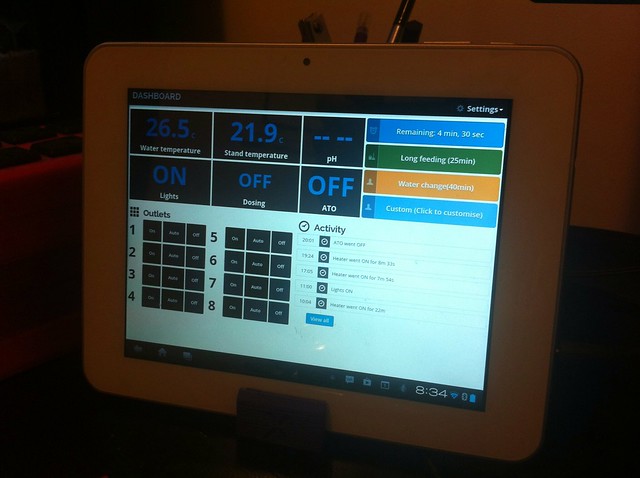

First prototype using an Android tablet.

The natural solution was to check the next available platform in the stack. We evaluated all the high-end micro controllers, such as the RaspberryPi and the Beagle Bone. We even have simple version of the controller, written in Python, to run in these Linux based devices.

It seemed like a promising idea, if it wasn’t for its cost. For not much more we would be able to buy an OEM Chinese Tablet, which would be much more powerful, comes with Wifi, Bluetooth and GSM and a large touch screen display.

The photo you see above is the first working version of the controller running in an Android tablet.

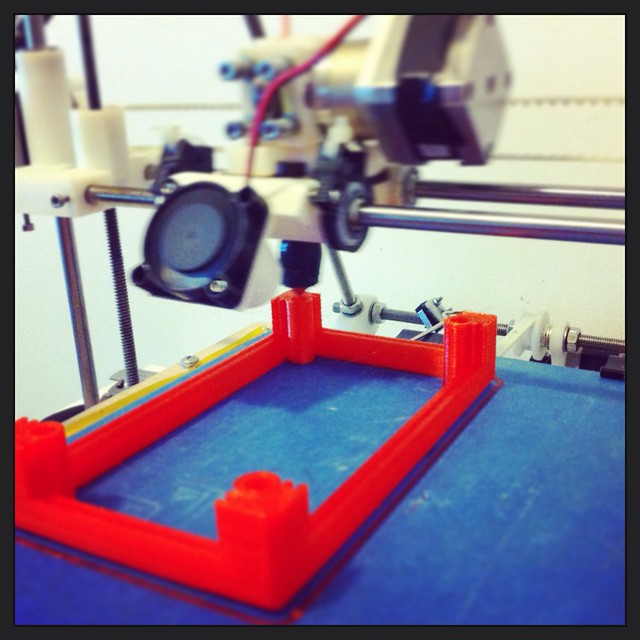

3D printed case replaces the cardboard enclosure.

Hardware and software were all in place, the communication protocol was reliable and the device was capable of recovering from erros. In other words, the system architecture proved to be stable and relatively easy to expand. On the flip side, the device was still running inside of a cardboard box. That is when in decided to jump into the world of 3D printing and we built our own 3D printer, an Open Source Prusa Mendel.

The photo below is our very first enclosure design, in fact the very first 3D design we have ever done. It was designed with OpenScad.

The 3D printing was another challenge in itself and it deserves another post.

First design of the Tablet Dashboard User Interface.

Dashboard running with the new design.

3D Design of the Dosing Pump Enclosure

Compact Quad Dosing Pump

Half of the enclosure, 3D printed with a Reprap Prusa Mendel printer.

Dosing pump enclosure being 3D printed.

Sensors box version 3.

No comments yet.